The basic philosophy of having such machines designed and made is different, although the required functions are very similar to packing coffee or tea and producing good quality kcups.

Here now, we choose the European SR6 machine, the European best kcup filling and sealing machine, as an example and compare it with the challenger: the China-made EXPAK CP5006V kcup filling and sealing machine.

We will compare the two machines from these below aspects:

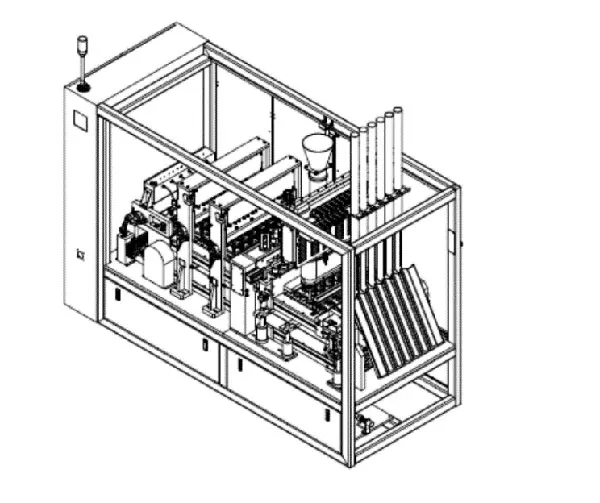

First, let's look at the China challenger, EXPAK CP5006V k cup filler, and sealer machine.

From the bottom design philosophy, this machine is driven by a mechanical shaft and gearbox system, located in the bottom as the typical and reliable drive system for such machines for the past ten years that EXPAK does not change but only improved upgrading with higher speed.

The machine's main components are all world first-class top brands such as SMC for air systems and Schneider for electric components; it is not world top. Still, it is best in China to make such machines, while other Chinese companies may consider more cost-saving and choose lower levels, such as Airtac for the air system and Omron for the electric system.The space between each station is quite open; this makes it more compatible for more optional functions, such as inline weighers, flavoring dosing, etc., based on different customers.

Upon customer needs, it is ready to fit standard, barrier, compostable, and compostable barrier kcup or k-shot capsules, and as the same platform machine, besides packing kcups, this platform is also able to produce different capsules, such as Nespresso or Dolce Gusto with a quick change over tooling design.

Capacity speed: CP5006K machine has six lanes, and each lane can produce 50 pcs kcups per minute, so the total is 300pcs kcup per minute. (EXPAK also has the eight-lane model as CP5008K; however, to make a fair comparison here, we only list out CP5006K)

Main functions and features: the process of its tasks is complete as vertical loader infeed the kcups, check each lane cups ready, filling system to different dose products such as coffee, tea leaves or any soluble, standard equipped with high exchange nitrogen flush system, place lidding then dual sealer to seal the capsule twice, take out the finish kcups and place on the exit conveyor belt.

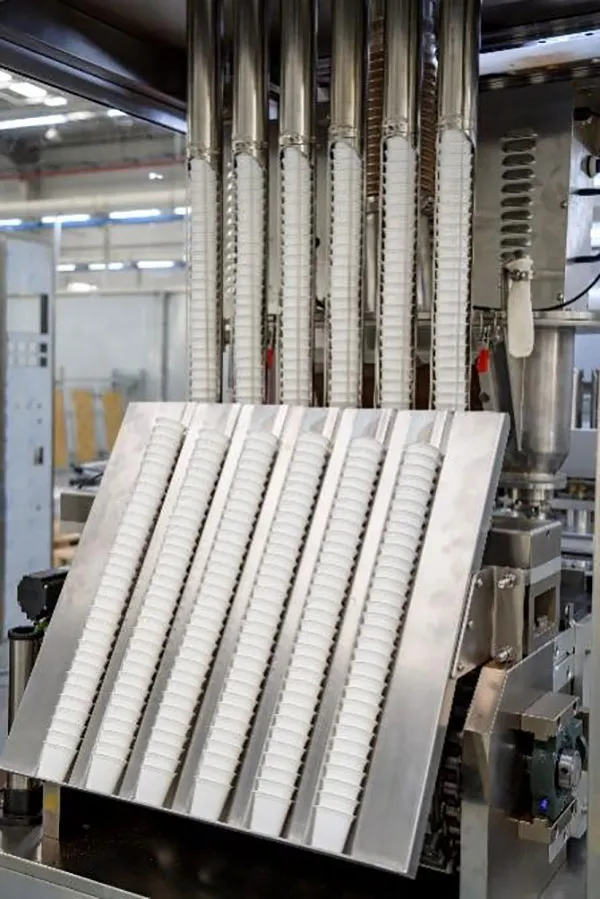

Vertical cup loader infeed system is a new market trend and made the machine more compact and take a small footprint, making the customer easy to place in a limited size workshop.

VERTICAL LOADER SYSTEM

FILLER OUTPUT NOZZLE WITH QUICK CHANGE OVER DESIGN

A 10" touch screen could control the machine, while temperature control is listed below. The interface is standard with two languages: Chinese and English; however, what is excellent is that EXPAK also offers other languages such as Spanish, Arabic, and Russian, and it is FREE!

The machine has compact size as, with vertical loader design its length as 3000mm(9.85ft) width 1110mm(3.6ft), and height as extendable between 2000mm-3000mm (6.5ft-9.85ft)

Its weight is also controlled well as ~1500kg(3300lb), so a regular forklift truck can move it freely in the workshop, and you don't need to pay for a third party with a bigger forklift.

The investment idea: this complete machine is between USD60000-USD80000 based on different optional functions customers can choose; this stands for the typical high-quality machine at an excellent price.

Delivery time: with the standard platform, the EXPAK machine launched excellent fast delivery plans that such a machine can be delivered within 30 days. This includes accurate run tests for at least seven days packing coffee into cups real production run.

This machine requires electric and compressed air to run.

The electric power is 15kw and 220V usual North American standard power.

Compressed air is 30NM3 per hour at pressure 0.6-0.8Mpa.

So it is generally eating a lot less than European machines if you compare in a long term period.

The most crucial side is you don't need to worry about maintenance.

These machines are customized, so machines are machines; once a customer wants to buy a machine for long-term business and production use, we have to think about potential problems that need to be solved. The EXPAK machine is a simpler design with clear space between different working stations, so it is much more user-friendly and does not require extreme technical skills to use and maintain daily. You can understand it when you look at each station, and a regular technician could efficiently operate it. We believe this is the essential feature for any international customers that when things can be done by your staff and not require an expensive technician to maintain the machine, better than having to pay for costly engineers or having to fly over the European technician and wait for service that your stuff is not able to handle or fix some problems, it will be a big hurt to your business as production is stopped.

On the spare parts, as it uses open market components brands like Schneider and SMC, etc., the customer can also buy from a local source to replace the needed spare parts. And with the opener space we designed and left, it is also easier to change positions. This is another side to guarantee non-stop production in the kcup business.

EXPAK has over ten years of experience as China's player; compared to European companies with more than 20 or 30 years of history, the younger is more open and flexible. They are available to explain and offer all details to let you understand and learn anything about the machines; this will help you know better before you buy and better run it to help your business when you have it—and also being willing to listen to the customers' needs during the past years and improve the machines to fits better upon all different customer ideas. All is to serve the customer to work for production.

Another essential side service is that EXPAK also offers packaging materials service, so if the customer knows little and needs help on packaging materials such as empty kcups and 2.0 lidding, they are also ready to help; this means a lot for them those who are just entering this business field.

For the after-sales service, this is the premium side that EXPAK is being famous for; they have an after-sales team ready for 24hours response, so customers never worry, and with modern technology applied, when a machine is with remote internet dial-in box, then the machine could connect online to watch and know what is happening by the team in China, and then communication online to help diagnose by voice or video calls with the professional team, it is as fast as immediate response and guesses what, this is FREE that they have done for customers in the past years.

Besides, they have frequent free service visits every year even if the customer is normal, offering free maintenance service in the North American area.

SR severe is defined as medium production. It has four lanes and six lanes, two models.

Each lane is maxed 60pcs per minute, so SR6 has six lanes up to 360pcs per minute. (SR4 as four lanes up to 240pcs per minute), Six routes are maxed and do not have eight lanes.

The central drive system is now a camshaft system that is mechanically driven to each connected function station.With a rotated touch screen of 15 inches panel, the operator can easily watch the production and control the screen simultaneously.

The filling system is also auger type and dosed through an auger system driven by a Brushless motor.The machine is prearrangement for nitrogen tunnels and an inline weighing system.

First, it eats a lot more, power consumption is 18-25kw, compressed air 55NM3 per hour, and nitrogen is 65-95NM3 per hour; that is a lot!The working station is very compact, and the space is very narrow, so it is not friendly to be touched, and maintenance is being complicated; the technician would not be easy to work on each station to fix it when the problem happens. It would help if you prepared a very skilled technical team to use the machine, which will be very difficult to find, as there are very few there to be hired yet it is hugely expensive to keep them.

EXPAK machine is smaller so as for flexibility to be placed anywhere, more straightforward structure and the wider space so more accessible for maintenance work. It does not require a skilled team to use it; the Chinese team offers a more friendly way to service all kinds of customers, and most important: the much lower price made it a much smarter choice than the European machines to allow more potential customers to produce cups and enter the kcup business.

Thank you for contacting us. We will reply to you as soon as one of our agents is available

Close this Window