Just as its name is a coffee capsule filling and sealing machine, one of the main functions is to fill coffee into the capsule, whether a k cup or a Nespresso cup.

So today, we are going to introduce this station, from the main structure and the detail of each part, and compare some different solutions for refill and drive systems.

How does it work?

First, lift the coffee into the hopper when your coffee is ground-ready, either in a super sack or a big bucket on the ground. So, the first step is to feed this coffee into the machine's filler hopper. We have two solutions, one as a vacuum air conveyor; another as a mechanical screw conveyor.

Then, when coffee is in the hopper, precise augers inside the hopper will spin and push the coffee into each cup, which is the primary step as filling; this is the bottom half inside the hopper.

Several big arms spin the coffee; this is an agitator to make the coffee flow smooth and help the coffee get into the bottom half for the auger filling job.

At the top of the hopper, a level sensor always checks the material (coffee or tea) current level; once low, it tells the PLC and needs refeeding by the ground feeder to reload more material.

This is the complete cycle; the coffee flow from the ground to the hopper, then the hopper's upper half and bottom half. Now let's check the details of each.

1. Coffee Conveyor as reload system

Reloading (refilling) is to load more coffee into the filler machine's hopper.

Mainly we offer two ways to conveyor or lift ground coffee into a hopper of filling machine.

Vacuum Conveyor and Auger/screw Conveyor

Vacuum Conveyor:

![Vacuum Conveyor Vacuum Conveyor]()

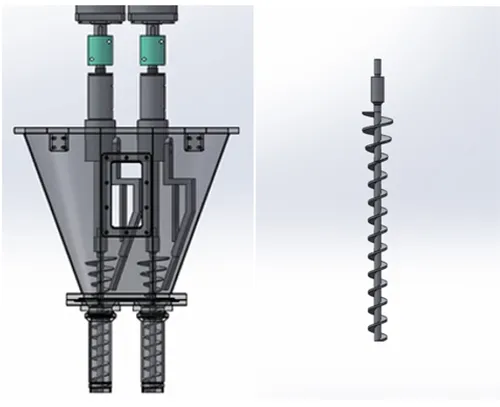

As the pic shows, the left side is the Vacuum Conveyor equipped on the machine; the right side is the main part

Vacuum conveyor as standard part using pneumatic way to suck and transport coffee into the hopper of filling machine.

On the ground, there is a pipe that sucks the coffee. You will need to move it around to keep the coffee eaten and lift it by the plastic pipe.

On the top of the machine, there is the air system that generates the vacuum and controls the sucking process; once some coffee is lifted to the top, there is a gauge inside the airhead, and the opening of the gauge release the coffee; this is the complete cycle of how air conveyor works.

You can set the timing as left side button, how long to open the gauge, for example, six means, keep gauge open for 6 seconds. The right side button sets how long it keeps sucking; for example, if you put 3 or 4, you can keep sucking coffee by 3 or 4 seconds.

Auger/Screw Conveyor

![Auger Auger]()

The second and better way is a screw conveyor lifter.

This is a mechanical way to use a big auger inside the pipe to auto-lift the coffee into the machine hopper with a big bucket so it can contain more coffee. This is not included in a standard machine quote but as an optional choice. Still, as it is a mechanical drive, it guarantees better coffee quality.

A brief comparison of air conveyor and screw conveyor:

- An Air conveyor is a small system requiring no space, while a screw conveyor needs to put the ground bigger hopper to receive coffee.

- The screw conveyor is noisier, but the screw conveyor also has some noise from the vibration part.

- The screw conveyor is a little higher budget than the air conveyor (about 5K USD)

- Screw conveyors retain a better density of coffee, which is better for filling accuracy.

- Screw conveyors retain more aroma by mechanically moving the coffee cup.

Conclusion: when your budget and space allow, take the screw conveyor.

NOTICE: screw conveyor is recommended for all customers who can accept the size and budget allowance; also, for espresso coffee which is fine, grinding is highly recommended, such as Nespresso and Lavazza blue, etc.

Because by air conveyor, the ground coffee will exchange with the air(oxygen) and it will lose the good aroma while this auger system is the mechanical way to keep better aroma almost no loss.

2. The auger filling system

Now let's look at the critical system, the filler station that fills the coffee into each cup.

![Auger filling Auger filling]()

Pic of Auger Filler

In the bottom half, there are several precise augers. At the bottom half, the auger spins and pushes out the coffee to the bottom and finally comes out from the exit nozzle and gets into each capsule.

There are three things:

- The auger is precisely made; this would guarantee stable and accurate filling.

- (Please check the Pic Auger Filler) The auger has a different diameter from top to bottom. This particular design is to reach both speed and accuracy. The top part of the auger has a bigger diameter, so more coffee is taken to be pushed into the bottom half filler tube.

Then the bottom has the smaller diameter auger part and reaches a higher filling speed. The coffee is also being compressed and becomes firm; this density change could allow the limited capsule/cup to be filled with more coffee.

- The cup is covered and sealed during the filling process; this would help a lot to prevent fine coffee granules/powder fly out, especially when they stay on the cup's mouth, and then sealed on the cup edge is related, and this isn't good for sealing.

What motor drive the auger is very important.

This filling is essential, so how to control this filling process?

The answer is the motor that spins the auger.

The motor for this station is so important that it needs to control the spinning speed of the auger to adjust the ground coffee amount, so let us the comparison of multiple motors commonly used in the coffee pod packaging field on the market.

● Stepper Motor

What is Stepper Motor?

A stepper motor is a motor that rotates a shaft by stepping (that is, moving at a fixed angle). Its internal construction makes it possible to know the exact angular position of the shaft through a simple step count without the need for sensors.

Stepper motors also include a fixed part (stator) and a moving part (rotor). The stator has gear-like protrusions with coils wound around it, while the rotor is a permanent magnet or variable reluctance iron core.

![Stepper Motor Stepper Motor]() Advantages:

Advantages:√Due to their internal structure, stepper motors do not require sensors to detect motor position. Stepper motors move by performing "steps," so simply counting the steps gives you the motor's position at a given time.

√In addition, the control of the stepper motor is effortless. It also requires a drive but doesn't require complex calculations or adjustments to function correctly. The control effort is usually tiny compared to other motors. In addition, a high precision position can be achieved if microstepping mode is used.

√Stepper motors provide good torque at low speeds, maintain a good position and have a long service life.

Disadvantages:●Loss of step may occur when the load torque is too high. Since the motor's actual position cannot be known, it negatively affects the control. This problem is more likely to occur when using micro-stepping mode.

●Stepper motors always draw maximum current even when stationary, reducing efficiency and potentially causing overheating.

●The stepping motor has low torque and high noise at high speed.

Stepper motors are the best choice for a low-cost, easy-to-control solution that doesn't require high efficiency and high torque.

● Servo Motor

What is Servo Motor?

Nowadays, a servo motor is mainstream in single-serve capsule filling machines.

Generic term for motors that use servos, the servo system is an automatic control system that enables the output-controlled quantities such as the object's position, orientation,

![Servo Motor Servo Motor]() Advantages:

Advantages: Good speed control characteristics, smooth control in the entire speed range, almost no vibration, high-speed control, high-precision position control (depending on encoder accuracy), and rated operating area. It can achieve constant torque, low inertia, low noise, no brush wear, and is maintenance-free.

Disadvantages: The control is more complicated; it needs a servo driver controller box to output the signal. More parameters need to be set: acceleration speed, spin speed, and deceleration speed; see the picture below.

![Disadvantages Disadvantages]() Conclusion:

Conclusion:

Servo motor is better than stepper motors for better accuracy and maintenance-free.

In Expak filling machines, we are only applying the brushless servo motors.

It can keep higher precision for controlling the auger spin speed, and no need to maintain or replace the brush.

Also, to make it easier to change different coffee amounts, instead of changing all three parameters, we designed a formula function that you can easily change the target weight by one setting change. The program will automatically calculate each setting accordingly and make the complete set for a servo to work.

3. Agitator and level sensor as a detector

Agitator

The precise small auger is to push coffee out and load it into the cup to make it a complete automatic coffee filling process. The big screw auger feeds more coffee from the ground and reloads it into the hopper; the agitator is between these two, which helps to keep the coffee flow stable.

As we explained above, the agitator is in the upper half of the hopper, attaches to the auger, and spin in the opposite direction of the auger to keep the coffee uniform; this is necessary to maintain the density in case the coffee becomes too firm and tight.

Level controller sensor

A level sensor is to watch the coffee level inside the hopper; we prefer fork type level detector inside the hopper for coffee material level inspection; when the coffee granule is lower, it sends a signal to PLC, so PLC knows the material is low and give another signal to automatic turn on the refilling system- the screw conveyor (or air conveyor) and start to bring in more coffee into the hopper. If it tried, but still coffee is low, which means, fail to reload, in EXPAK machine, we made another voice system that PLC would let the broadcast make an alarm to remind the operator by real voice as: "please reload coffee." So even a fresh operator could easily know what is happening and needs to load more coffee.

![Leverl controller Leverl controller]() Quick solution to solve problems that happen with the filler station:

Quick solution to solve problems that happen with the filler station:

1. Q: filler auger does not spin, no coffee comes out, code AL006 on servo controller (or screen show "Feed servo one fault").

A: clean the filler station and reboot the machine (or soft button to clear the alarm code and press the start button again)

Comment: this is the most frequent problem, most case is that the coffee sticks to the auger and then create an overload on the servo motor, so to be self-protection, the servo motor stops and shows AL006. This usually happens when the grinding is not stable, such as the coffee is too fine grinding, or the coffee is rich in oil and sticky. It happens more with Nespresso than Kcup because the average grinding in Nespresso capsule is much more delicate than with Kcup coffee.

2. Q: unstable weight of coffee filled/ accuracy of filling is not stable.

A: try to improve the setting, mainly to change the filling speed and ratio settings, and speed up the agitator would also help. Contact the Expak team to improve the setting parameters.

3. Q: The agitator function does not spin/work during filling.

A: Check the screen and turn on the agitator button or speed up the agitator speed when needed. Check whether the agitator motor could rotate; if not, hit the "agitator" to the running status through the touch screen

4. Q: too much coffee out of the cup may cause sealing problems.

A: this main is static electricity problem, which several ways could solve as, using a more significant anti-static device or replacing when old. Ensure the cup is covered by the filler output head to reach the seal during filling; sometimes, you need to check whether the bottom pushing up cylinder is aimed at the center.

Also, if the coffee has static, slowing down the main speed could also improve such problems as giving more time to wait for the filling to be done inside the cup.

Maintenance guide on filler system:

|

Every day before production

|

1. Material hopper is balanced.

2. Augers are straight without bent.

3. Filler head is centered with the hole center.

4. Cup lifter is in the center, and the push cylinder is moved smoothly. The slide bearing is smooth. Replace if needed.

5. Stir mixing is smooth, no stuck.

6. Stir blade is installed properly.

|

|

3 months

|

Open the top rack cover to check inside.

1. Wiring is ok.

2. Plug is tight.

3. Remove the dust or powders related to motors or the covers.

|

|

6 months

|

1. Chain is tight and sprocket teeth are complete, replace if needed.

2. When power is off, manually spin the agitator to confirm it is spinning freely. |

Publication Date: 4/28/2022

Category: Product Events